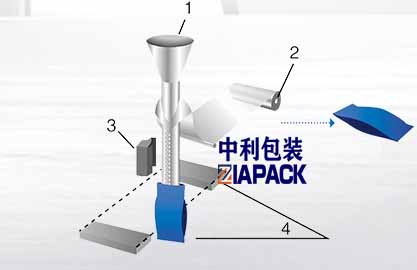

Automatic VFFS packaging machine as the main packaging machine which can use roller film to forming filling sealing and packaging different product . It is a machine with strong packaging capabilities and can be applied to all kinds of small particles or powders. The biggest feature is continuous packaging, which greatly saves time and labor costs.

According to different materials, packaging machines can be divided as

VFFS packaging machine for powder product

VFFS packaging machine for granule product

VFFS packaging machine for liquid product

The packaging speed of ZL series vertical bag forming filling sealing packaging machine is not only fast, but also can automatically seal and cut automatically. It can not only be used for packaging materials without trademarks, but also can be used for high-speed packaging with materials printed with trademark patterns. General machinery will make wrong judgments due to the color on the packaging material, which will cause packaging errors. In order to eliminate the error, the design of the packaging machine must consider the problem of automatic positioning, and the continuous photoelectric positioning system is divided into the forward and retreat type, the brake type and the synchronous type of the two transmission systems according to the error compensation working mode.

In fact, the principle of the packaging machine is very simple. It belongs to a PLC programmable program to achieve a series of packaging actions.

The packaging machine will have a set of its own system. The machine will strictly follow this when it is working.

Feed the material first, then weigh it. When the required weight is reached, the system will automatically control it to stop, and then proceed to the next process. After the material enters the packaging bag, the packaging bag's sealing equipment is controlled by the computer to seal, and then the cutting equipment cuts off the packaging bag. The packaging system is not fixed, customers can adjust it according to their needs. With the increasing demand for products in food, medicine, daily necessities and other industries, traditional manual packaging operations have been unable to meet the needs of the market, and it is inevitable to seek equipment that automates production and improves production efficiency. Thus gave birth to a high-quality, high-performance fully automatic packaging machine.

Packaging machinery can be roughly divided into vertical form fill seal machine and pillow packaging machines. It is suitable for liquids, powders and granules with good fluidity. It can be packaged mainly by its own gravity and mechanical action. Vertical packaging machines generally have two functions, cursor cutting and fixed-length cutting. The two cutting functions are easy to switch. Which packaging method is used depends on the packaging film. Packaging films are roughly divided into cursors and no cursors. Packaging films without cursors are cut to length, and vice versa, cursors are used to cut.